변압기 제조 세계에서 권선 공정은 귀하의 운영의 핵심입니다. 하지만 여전히 구식 또는 수동 방식으로 호일 권선을 사용하고 있다면, 일련의 비용이 많이 드는 문제에 직면할 가능성이 높습니다. 즉, 품질의 일관성 부족, 느린 생산 속도, 상당한 양의 재료 낭비입니다. 그렇다면 현재의 권선 공정이 귀하의 효율성과 수익에 해를 끼치고 있습니까?

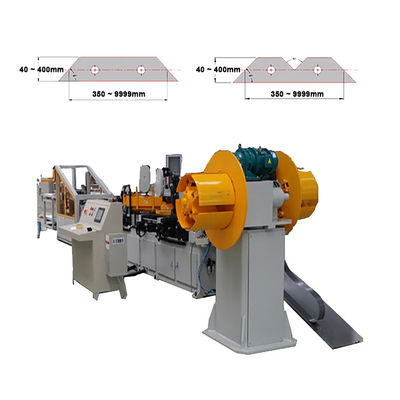

변압기 호일 권선 기계는 이러한 문제에 대한 현대적인 해결책입니다. 당사의 기계는 호일을 공급하는 것부터 코어에 정확하게 권선하는 것까지 전체 권선 공정을 자동화하고 최적화하도록 설계되었습니다. 첨단 컴퓨터 수치 제어(CNC) 시스템을 사용하여 수동으로 달성하는 것이 불가능한 수준의 정확성과 반복성을 보장합니다. 이러한 자동화는 더 빠르고, 더 안정적이며, 더 일관된 생산 출력을 가능하게 합니다.

뛰어난 속도: 당사의 기계는 수동 작업자보다 훨씬 빠른 속도로 코일을 권선할 수 있어 생산 시간을 대폭 단축합니다.

타의 추종을 불허하는 정밀성: CNC 제어는 모든 권선이 완벽하게 균일하도록 보장하며, 이는 변압기의 성능과 신뢰성에 매우 중요합니다.

최소화된 폐기물: 호일 장력 및 배치에 대한 정밀한 제어는 재료 낭비를 줄여 비용을 절감하고 수익성을 향상시킵니다.

인건비 절감: 단일 작업자가 여러 대의 기계를 관리할 수 있어 인건비를 절감하고 생산성을 높입니다.

당사의 변압기 호일 권선 기계를 선택함으로써 귀하는 단순히 장비를 업그레이드하는 것이 아니라 제조 공정의 미래에 대한 전략적 투자를 하는 것입니다.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!